Porcelain insulator manufacturing process choose insulator materials crash of material mixture of all kind of materials shaping drying glazing and sanding electro drying install with.

Ceramic insulator manufacturing process.

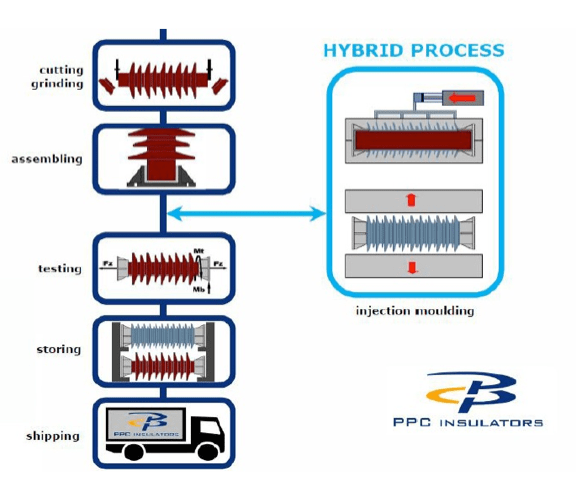

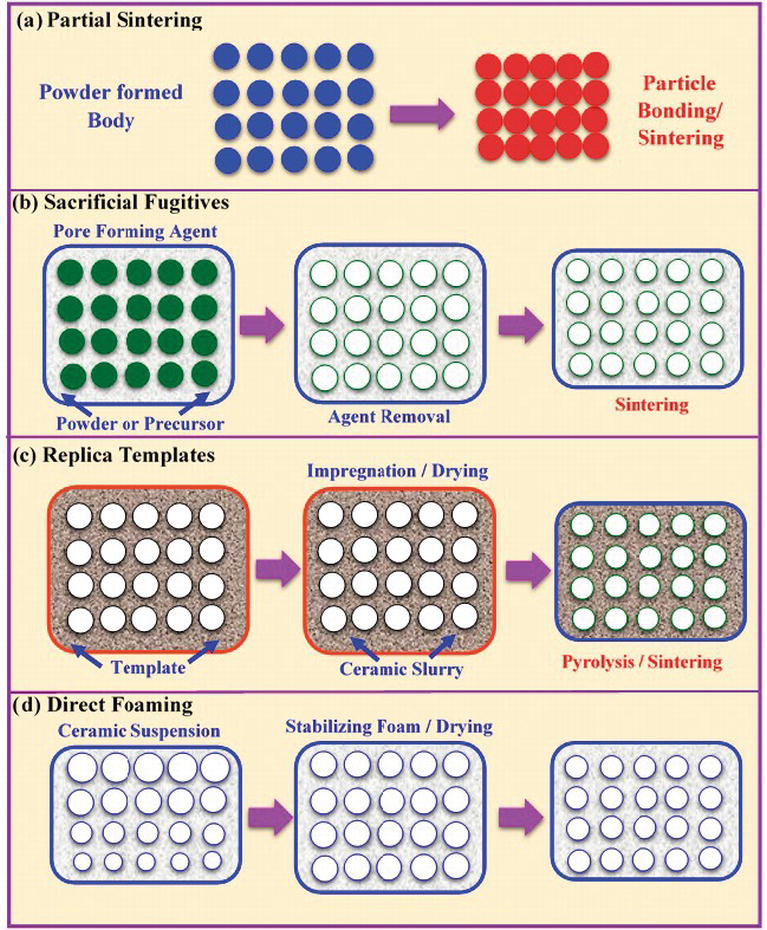

There are different production process methods are used in the ceramic production process.

Porcelain is made from a refined white clay called kaolin and is fired at temperatures as high as 2 600 fahrenheit.

Glaze is a layer of decorative glass applied to and fired onto a ceramic body.

Types of insulators 1 pin insulators.

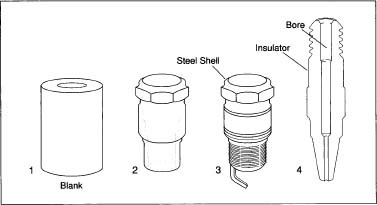

The term ceramic forming describes the process of production of ceramic components from natural or synthetic raw materials.

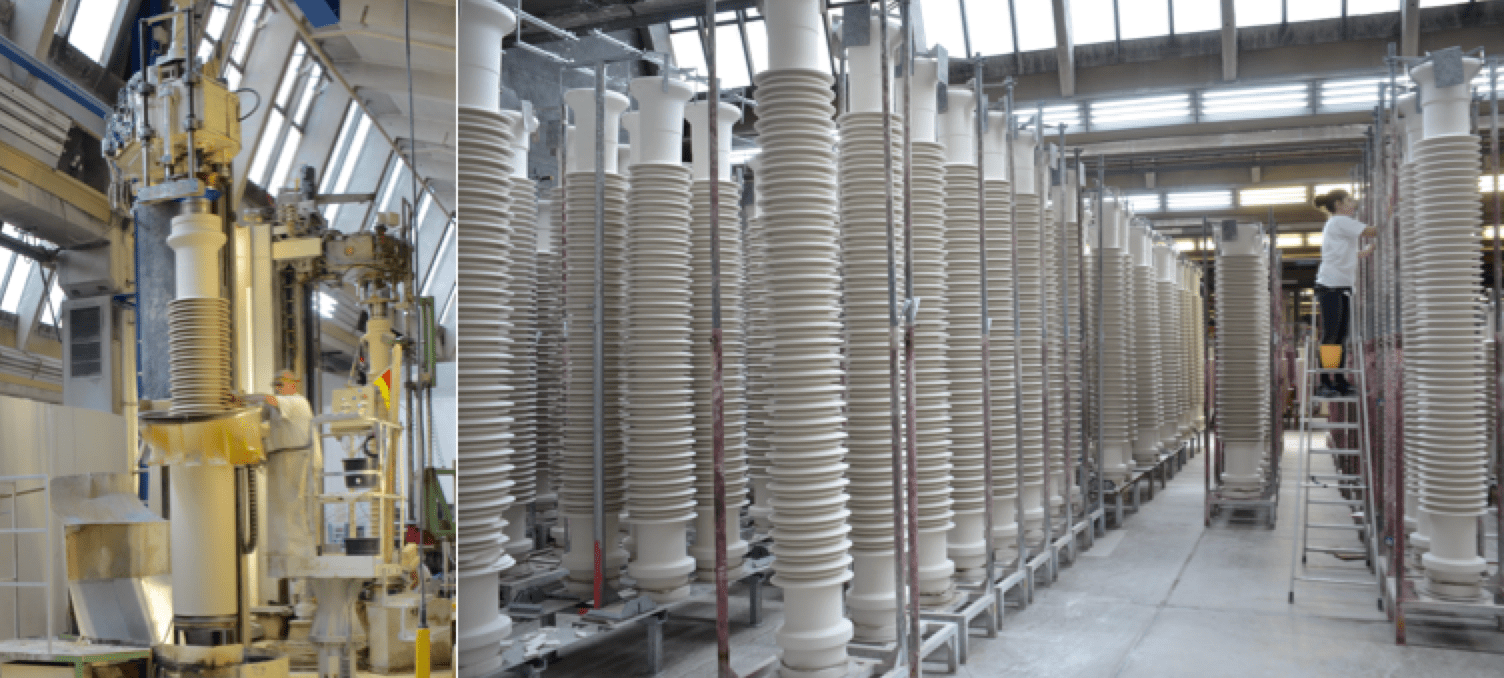

Production of ceramic electrical insulator.

Porcelain also has a solid color throughout usually white.

Has developed low temperature sintering.

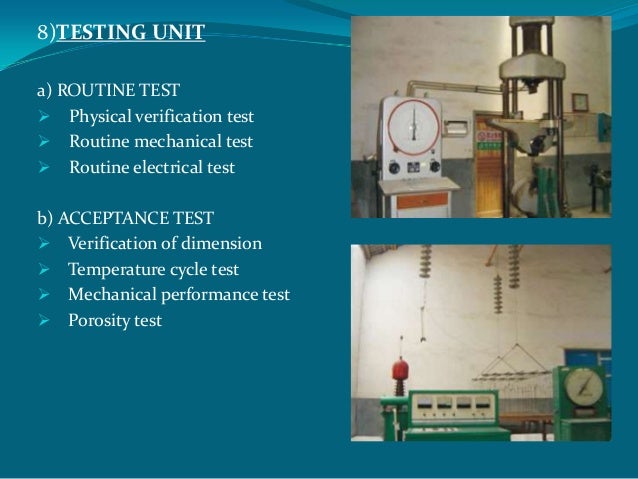

Internal quality control after the subsequent assembly of metallic fittings the production process is complete and the insulator from high performance ceramics is tested in accordance with international standards or customer specifications in the on site lab.

Manufacturing process of porcelain insulators 1.

Electric insulator market worth 13 34 billion by 2023.

An insulator is a material that does not conduct electrical current.

Vacuum is also an insulator but is not actually a material.

Insulating materials include paper plastic rubber glass and air.

We will discuss all the production process methods used in the ceramic industry.

During the subsequent firing the ceramic structure with its very high hardness is created.

A japanese manufacturer has developed high strength porcelain for electrical insulators whereas murata manufacturing co.

The manufacturing process.

The forming machine is fully automatic control machine the production process include green body enter machine auto forming is controlled by the computer.

It is sometimes referred to as china because the manufacturing process was developed centuries ago in that country.

Porcelain insulator manufacturing industry.

2 solid post insulators.