Ceramic fiber blanket is manufactured from spun ceramic fiber and is needled to provide exceptional handling strength for high temperature insulation applications.

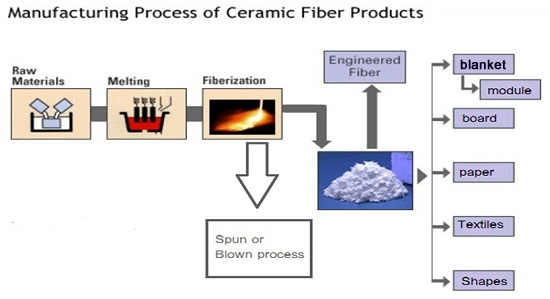

Ceramic fiber blanket manufacturing process.

Ccewool ceramic fiber blanket manufacturing process.

Ceramic fiber blanket packaging type.

Ceramafiber ceramic fiber blanket by ceramafiber insulation 8 2300f 1 x 24 x 25 feet for wood stoves pizza ovens kilns forges more 8 pound 2300 degrees 4 8 out of 5 stars 101 98 99 98.

Long total of 10 sq.

Also it is the unmatched quality that has made us a prominent manufacturer of ceramic fiber products.

Ft is used for various applications in the metal ceramic and glass production industries as well as in fire protection and aerospace applications.

Ceramafiber ceramic fiber blanket by ceramafiber insulation 8 2300f 1 x 24 x 25 feet for wood stoves pizza ovens kilns forges more 8 pound 2300 degrees 4 8 out of 5 stars 101 98 99 98.

In the surface treatment process in order to prevent shots contained in cf from falling onto and damaging the.

Blanket is typically offered in three standard grades referred to as commercial high purity and zirconia grade.

Ceramic fiber blanket 6 density 2300 f 1 in.

Thick x 24 in.

Ceramic fiber blanket production.

Since our inception in 2005 we are a proud manufacturer of heat insulation products in form of ceramic fiber bulk blanket module and rope under simwool brand and ceramic fiber board under simvac brand.

2 2 types of ceramic fiber and manufacturing processes ceramic fibers are largely divided into vitreous alumina silica ceramic fiber vitreous cf whose service temperature is below 1 250.

12 25 38 50 mm.

The manufacturing process results in flexible insulation that.

.jpg)