Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed granted application number ep06825428a other languages german de french.

Ceramic extrusion binder type.

There are a wide variety of binders used in traditional ceramics including natural products like cellulose or clays and synthetic products like polyacrylates or polyvinyl alcohol.

Organic binders such as polyvinyl alcohol carboxymethyl cellulose and arabic gum are widely used to control the technological parameters required for green and sintered ceramic bodies.

A normal body binder must have several characteristics.

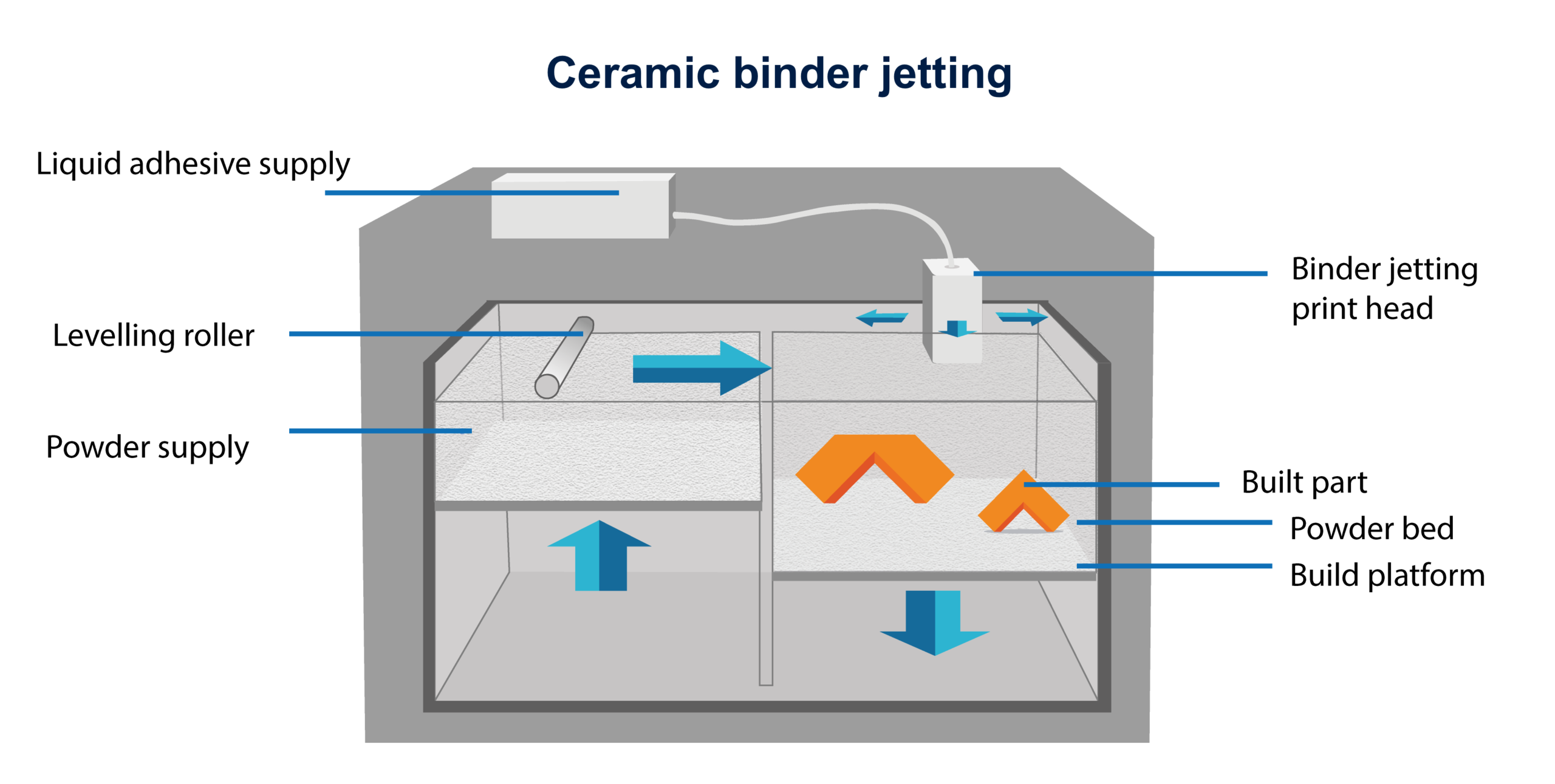

3 3 4 other technical ceramic powders for binder jetting 3 3 5 ten year forecast of powder ceramics materials for binder jetting 3 4 ceramic materials for material extrusion processes 3 4 1 cements for large format extrusion 3d printing 3 4 2 ceramic materials for extrusion and microextrusion 3d printing.

Ceramic extrusion lubricating binders binders extrusion prior art date 2005 10 20 legal status the legal status is an assumption and is not a legal conclusion.

Dry pressing also known as molding is one of the most commonly used molding methods.

A method for producing a ceramic article comprising the steps of providing a plasticized ceramic precursor batch composition comprising an inorganic ceramic powder batch composition.

This forming process consists of forcing a plastic mix of a ceramic powder through a constricting die to produce elongated shapes that have a constant cross section.

Currently the use of the first type of liquid binders in combination with solid binders is the most common.

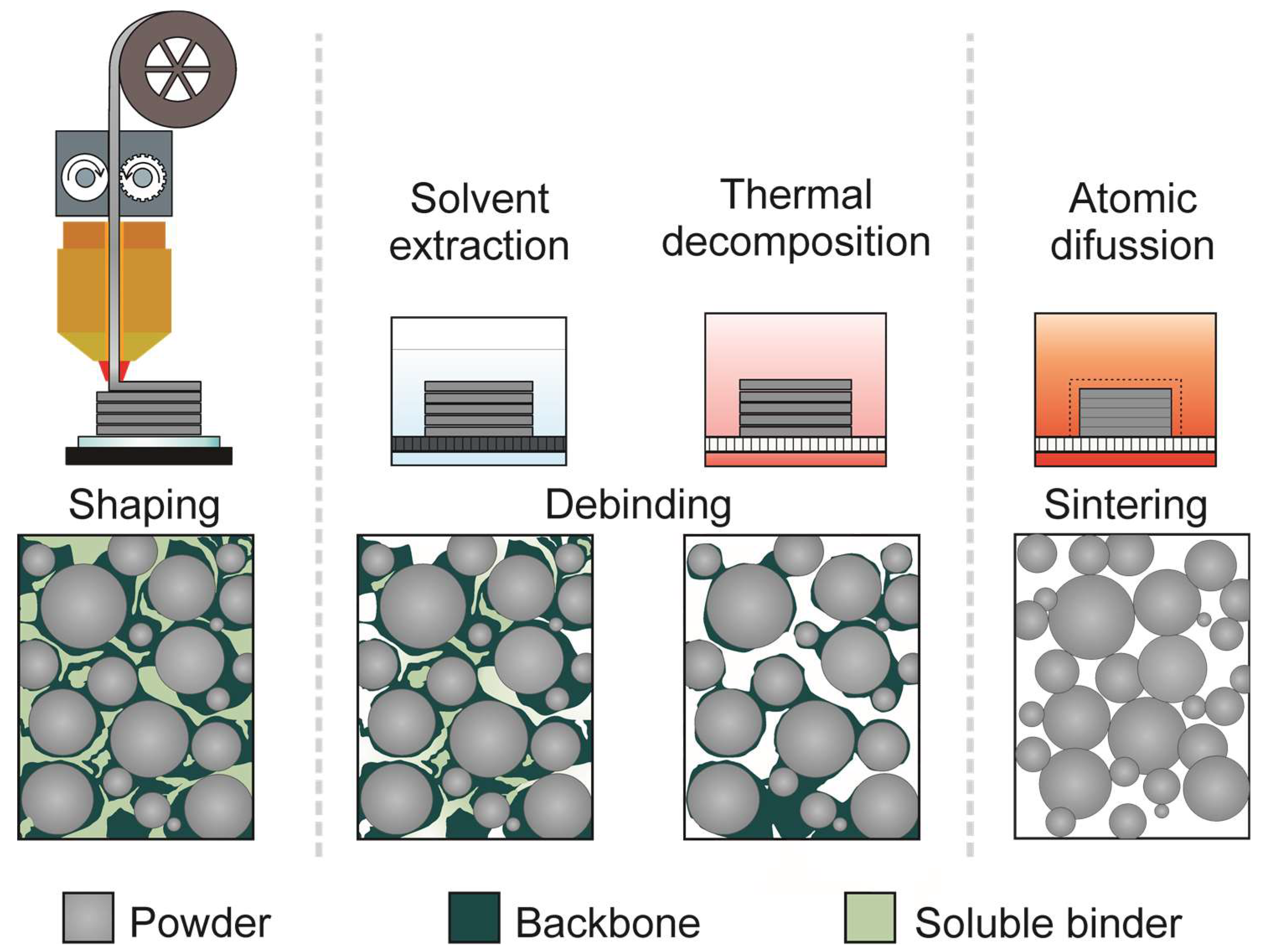

Diw ceramic 3d printing involves preparation of highly viscous ceramic slurry by homogenously mixing the ceramic powder with a polymeric binder.

There are two types of combinations for these two binders.

A variety of processes equipment and materials are used in the production of a three dimensional object via additive manufacturing.

It must easily burn out at low temperature.

It must leave a minimal amount of ash after firing.

This slurry is extruded using a screw extruder or a compressor in a layer by layer manner to build 3d structures.

For special ceramics of different uses manufacturers often adopt different molding processes.

The powder mix consists of a fine ceramic powder with the appropriate additions of binder s and plasticiser s to give the desired flow properties rheology either cold or when heated prior to being forced through the die.