Incoming pcb requirements for cbga freescale semiconductor.

Ceramic bga reliability.

Ceramic ball grid array packaging assembly reliability freescale semiconductor.

The cookies we use can be categorized as follows.

Ceramic plates and printed circuit boards pcb to assess solder wetting.

Assemblies with water soluble flux were cleaned in an electrovert h500.

In addition the utilized ceramic ball grid array cbga.

In addition to alumina al 2 o 3 ceramics we produce aluminum nitride aln with high thermal conductivity 150w mk as well as low temperature co fired ceramic ltcc packages with high 12 3ppm k and low 3.

A small tape based plastic bga package with 280 balls was included in the study 16 x 16 mm 0 8 mm pitch 9 x 9 depopulated center.

Also utilized was a 256 leaded and a 256 plastic bga package for evaluating and directly comparing manufacturing robustness and reliability.

Type 1 ceramic and plastic bga packages with nearly 300 i os.

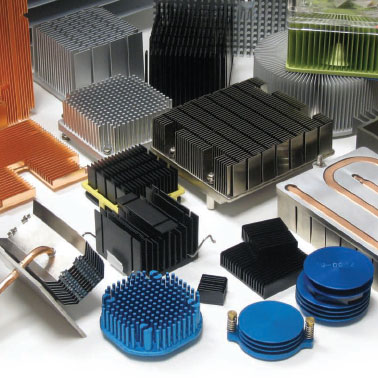

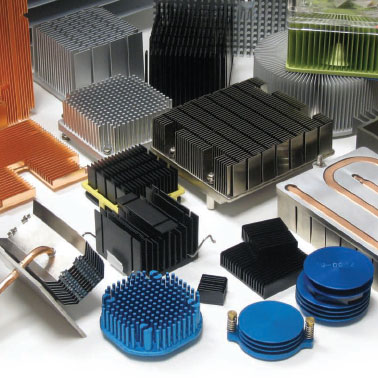

Typically these are packaged in organic or ceramic ball grid array bga packages which cover a wide range of package input output i o capabilities required for high performance devices.

Substrate based ball grid array bga flip chip bga quad flat leadless stacked chip scale flip chip csp xuejun fan moisture related reliability xuejun fan lamar edu higher performance smaller size cheaper price chip scale and wafer level packaging csp wlp.

Bga package component reliability after long term storage r.

Flip chip cbga is a common package for high end microprocessor devices.

Lower cte may be used to increase reliability.

Madsen abstract the white paper component reliability after long term storage texas instruments application.

Type 2 ceramic and plastic bga packages with nearly 600 i os.

Shih et al reliability of hitce ceramic bga packages to be published 2005.

Ball grid array bga assembly reliability jpl nepp presentation ipc 9701 csp thermal cycle created date.

Ceramic ball grid array package drawings bg accept and proceed.

Balls for this package are 90 pb and 10 sn and attached to the ceramic substrate using eutectic 63sn 37pb solder paste.